Illumina's Nano-imprinted flowcells

After the paywall break in my less than serious post on the NovaSeq X, I mentioned a few things that I found interesting about the Illumina presentation. One of these is that Alex Aravanis quietly mentioned that the X uses Nano-imprinted flow cells, which appear to be manufactured in-house in the UK, Singapore and San Diego.

This likely helps reduce manufacturing cost, likely in an effort to retain margin under increasing competition. So let’s talk a little bit about Nano-imprinting.

In regular a photo-lithographic processes an image is projected onto a surface, much like an analogue camera, most semiconductor fabrication is performed using these photo-lithographic techniques. But semiconductor manufacturers are always searching for new ways to make increasing small features at lower cost. One such method that has been proposed (but too my knowledge has not yet gained widespread adoption for semiconductors) is nano-imprinting.

As the name suggests, nano-imprinting masters make direct contact with the substrate and “print” a structure into it:

Typically you might make contact with a UV curable resin which is cured during the imprinting process. And as far as I can tell from their patents, this is what Illumina are doing. The use of nano-imprinting in NGS has also been documented elsewhere.

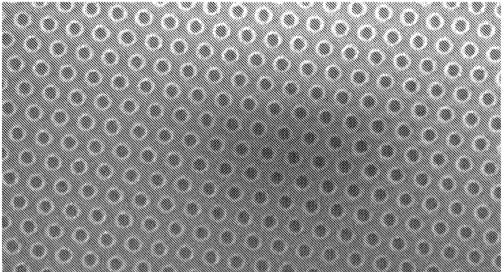

The patent shows a SEM image of an imprinted surface, and we can get a sense of the feature sizes they’re working with:

If we look at individual features, we can see they can fit ~4 wells in a square micron, with each well having a diameter of ~400nm:

The largest NovaSeq X flow cell is supposed to generate 25 Billion reads. Which is 158113 squared. So with 500nm per well that’s a 8x8 cm flow cell.

Unfortunately they didn’t give exact dimensions for the flow cell. Francis deSouza’s hands are also not well documented. But they look like pretty regular hands to me…

At a guess the substrate covered area of the flow cells looks to be ~7x10cm. This is roughly the area we’d need for 25B wells at 400nm well size.

However… only about 50% of the flow cell is covered by active wells. This suggests that they’ve pushed density higher on the 25B flow cells. Given that these are being shipped later than other flow cells, this could make sense. They also mentioned that the new flow cells are “320% higher density” than previously used. And given that Hiseq wells were already in the 500nm range, it would make sense if the NovaSeq X wells were significantly smaller.

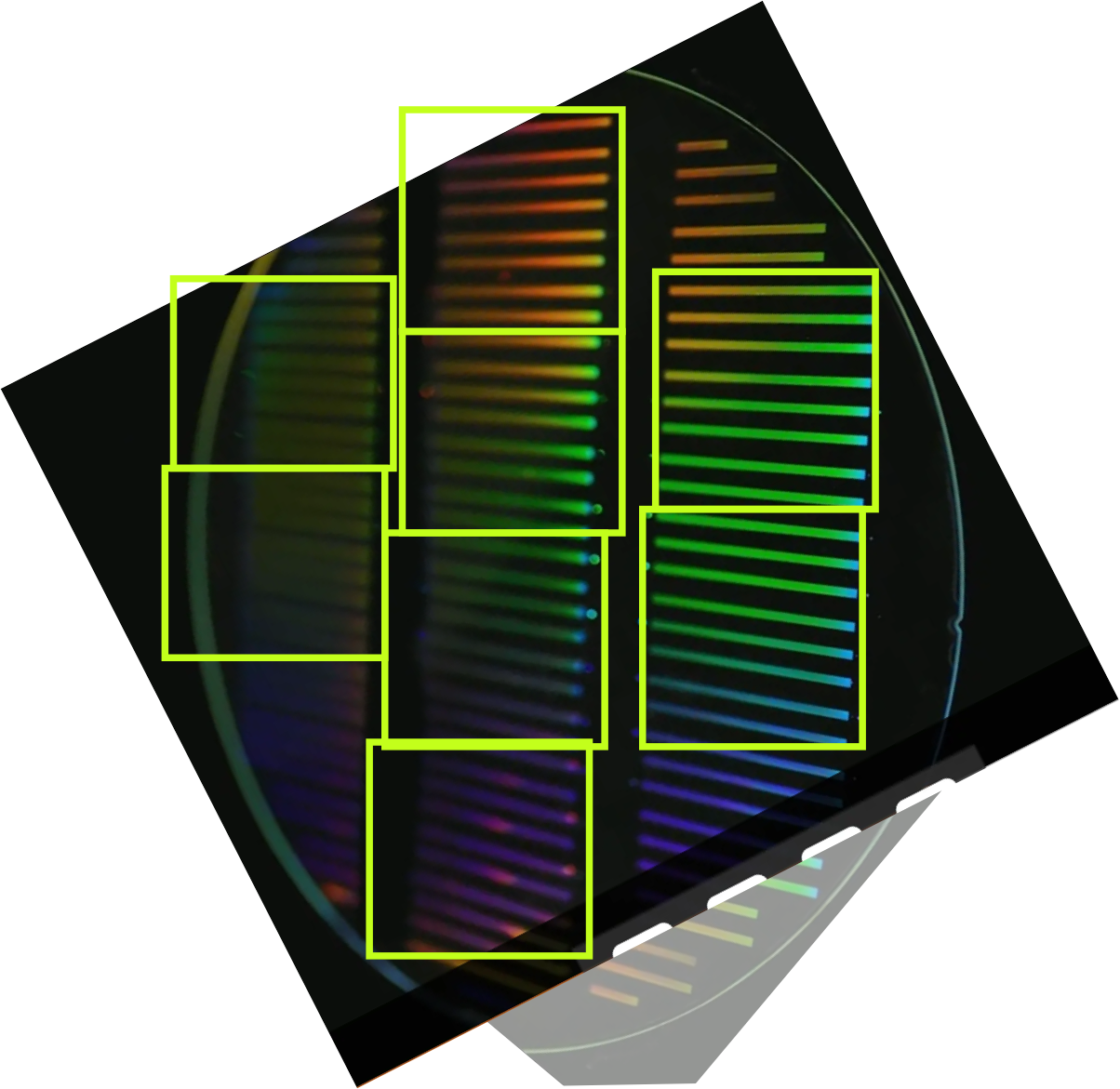

If we look at the wafer images from the presentation we can estimate that 8 25B flow cells will fit on a wafer, this also fits with the size estimate above, and their stated use of 30cm (12 inch) wafers:

It’s also clear that we’re talking about a glass substrate here:

I suspect nano-imprinting should be significantly cheaper for Illumina than photolithography. Some reports suggest that imprinting can reduce costs by as much as 50%:

But bringing the process in house seems to be the biggest win. Not only can they potentially reduce costs associated with outsourcing manufacturing but they can also gain more control over the process.

I’d imagine that most outsourced fabrication lines are setup to optimize for a minimal number of defects. In an image sensor a dead pixel means a useless chip. But for sequencing this isn’t a big deal. Even if 1% of your wells are inactive the run will still produce data within spec (Illumina yield ranges seem to be to up 6%). So potentially, Illumina could accept > 100 million defects per flow cell.

If this lets them extend the life of a nano-imprinting master at the expense of higher defect rate, this potentially could help them reduce costs significantly.

What’s harder to estimate is the exact dollar cost of a flow cell. Standard semiconductor fabrication seems to cost about $4000 on an older node, which would be $500 per flow cell, but this isn’t exactly a standard fabrication process...

Overall, using nano-imprinting I would guess they can push fabrication costs far lower than a standard semiconductor process (the patterning is after all, far simpler), perhaps into the $100 range…

But if you have any thoughts on this, please get in touch (new@sgenomics.org, @new299 on twitter, or in the comments section below).