10X Chromium Chip Patents

I now feel like I have a reasonable understanding of the 10X Chromium Controller, documented in the previous 2 posts. Fully documenting the pneumatic system took more work than I was expecting and paid subscriber revenue has been declining… I’m also looking to fund the purpose of a Raindance DropSense PCR system (~$600) to teardown as a comparison.

So… if the above is of value to you. Consider subscribing or throwing some money at the Patreon or the other substack1.

I’m also planning a wrap up post on 10X after I digested all this information… so stay tuned for that!

Anyway, here let’s take a quick look one of 10Xs patents which covers the system and chip.

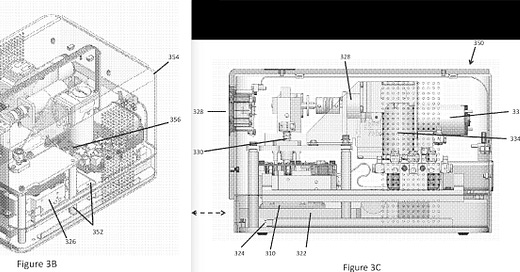

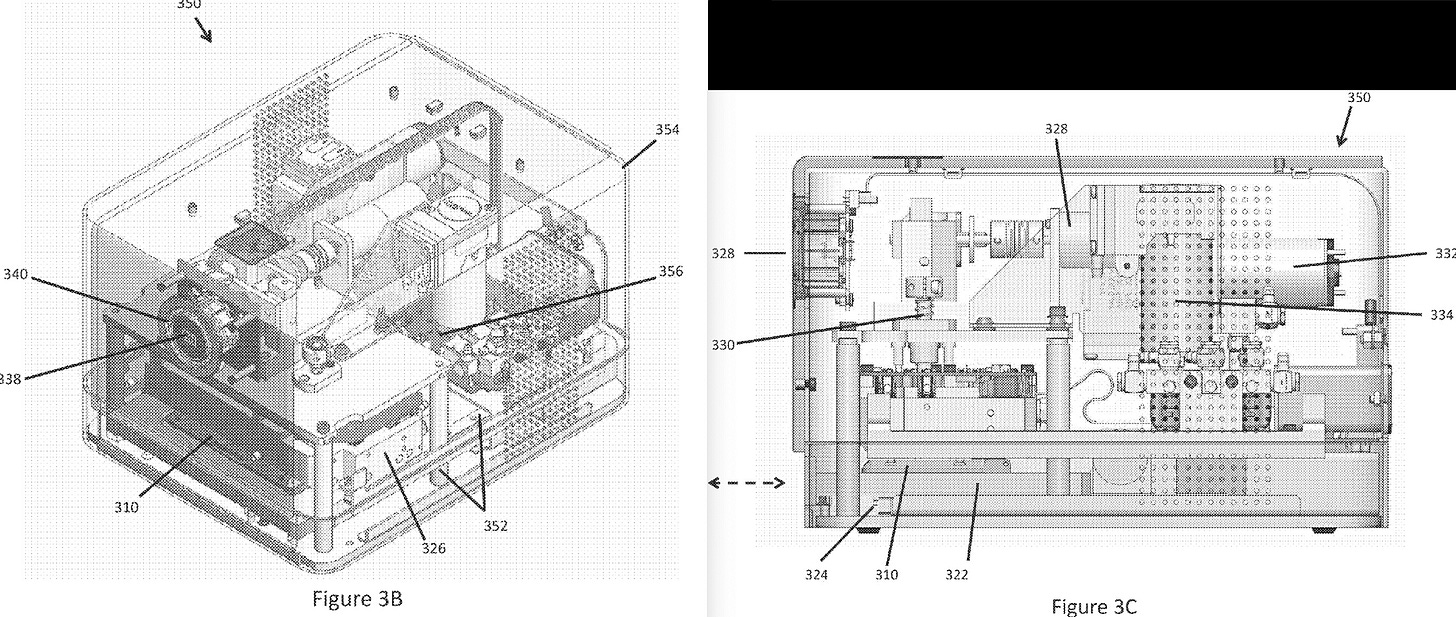

The CAD drawing shows a nearly exactly match with the teardown:

From what I can tell chips have gone through at least 3 revisions. In the first revision the instrument seems to dump droplets into an output well. In rev 3 they end up in the paritioning oil. The means they have a spare row of wells that goes unused:

Based on this post (which is well worth reading btw) this doesn’t appear to be a reaction to the BioRad litigation. But I’d be curious to better understand the motivation here2!

In any case the patent refers to the original chip revision. The partitioning oil seems to create a kind of “barrier” toward which beads and sample are pushed. This creates the droplets which are pushed out to the exit well:

Other patents show close ups of the structures themselves. Channel width seems to be ~100 micron. There’s an awful lot of nuance here and a comparison against a real chip would help clarify which structures are important to help prevent blocking, prevent lysis etc.:

Summary

These patents confirm a lot of what we saw in the teardown and pneumatic system documentation process and help explain a few things.

The reason we have negative pressure control on the top row is because this was where the output wells were originally located. This doesn’t seem strictly necessary any more3.

The patents also explain one of the reasons they monitor pressure so carefully is to shutdown the system in case of blockage. As previously noted, clearing blockages might be difficult. But it didn’t occur to be how catastrophic continuing operation with a blockage could be.

You could end up sucking (or pushing) reagents up into the instrument and pumps. This wouldn’t completely kill them but the resulting contamination and potential issues would be pretty horiffic.

This feels like a significant disadvantage of these pressure driven systems over syringe pump type approaches used elsewhere.

That’s all for now! Stay tuned for more posts on 10X!

Paid subscribers here (ASeq) will automatically be upgrade to paid on bitsof.bio which is a platform for slightly more informal posts and notes. But it’s also much cheaper…

As always please reach out if you have some insight here.

Or perhaps was never really necessary.